Many options are available for anyone who needs a finished product. Major CNC machining service providers offer the best option for those looking for precise and high-quality components. These machines are a great addition for spring exporting factories and manufacturers. CNC machines have unique functionality and features that allow for increased production within a very short time. Thus, this guide will discuss the reasons you should use CNC machines.

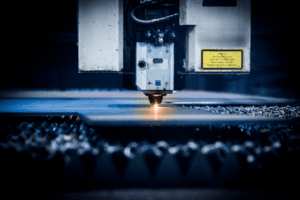

Combination of Laser Cutting and Machining

CNC machining can be costly. Laser cutting the part is a cheaper option. Laser cutting is an option that allows the part to be cut slightly larger than necessary. The machine tool can also go around the outside of a profile to ensure it meets the required dimensions. It is much easier to cut a 12-mm sheet of material and reduce it to 10mm using a machining center than it is to do it manually. Two ways are the most common way CNC manufacturing works. These plans can be used to make certain items.

CNC machining can be costly. Laser cutting the part is a cheaper option. Laser cutting is an option that allows the part to be cut slightly larger than necessary. The machine tool can also go around the outside of a profile to ensure it meets the required dimensions. It is much easier to cut a 12-mm sheet of material and reduce it to 10mm using a machining center than it is to do it manually. Two ways are the most common way CNC manufacturing works. These plans can be used to make certain items.

But, you cannot control the thickness of the sheet. The sheet’s thickness fluctuates throughout the day. It can be difficult to cut the same area even though you use the same sheet. This allows you to create the exact size product that you want. The product is not subject to any contortion from redundant heat. The manufacturing process results in a clean, straight edge that is free of any burrs or damage. If you are interested in high-quality precision segments, machining should be considered.

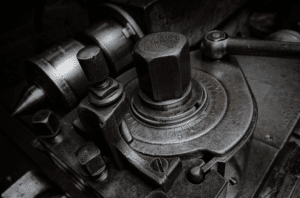

Hi-Tech Devices

It is important to look for the most recent technology when searching for CNC machined parts of the highest quality. Because technology is constantly changing and new inventions are emerging, ordering parts is better than investing in them. A supplier who has several CNC lathes or CNC milling machines will most likely have the most modern and popular machines. To maintain its efficiency, the equipment or machine will be regularly serviced by a team of specialists. You must deliver your products on time.

It is important to look for the most recent technology when searching for CNC machined parts of the highest quality. Because technology is constantly changing and new inventions are emerging, ordering parts is better than investing in them. A supplier who has several CNC lathes or CNC milling machines will most likely have the most modern and popular machines. To maintain its efficiency, the equipment or machine will be regularly serviced by a team of specialists. You must deliver your products on time.

Customers will not buy from you if they don’t receive their orders on time. Ask about the supplier’s track record and its functionality. A company with a solid track record will not hesitate to send you information. The ability to deliver on time is more important than the desire to spend less. You should therefore start searching for the best parts supplier. Also, choose a manufacturer that you can build a lasting and personal relationship.

Additional Information

You are not the only one who relies on CNC-turned parts for your business. These parts may be in stock, or you might want unique frames. There are two options: you can invest in your CNC cutter or CNC milling machine, or go to a CNC machine shop that will sell the parts. These are just some of the ways you can ensure your customers receive a high-quality CNC roll. You should look for professionals you trust and who will provide you with the best service for many years.